19th Century Porcelain Scent Bottles

Three porcelain scent bottles, 19th century, the first modelled as two putti and a fish, capodimonte mark to underside of base, no stopper, the second with two courting figures and a brocage stem, spurious gold anchor mark to underside, the last of…

Meissen Porcelain Scent Bottle, Early 19th Century

A Meissen porcelain scent bottle, early 19th century, 14 cm high

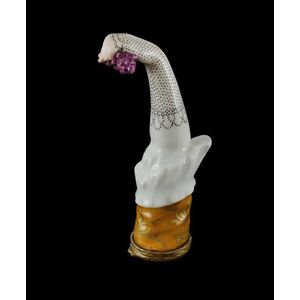

Meissen Porcelain Grape Scent Bottle with Gilt Cover

19th century Meissen porcelain scent bottle. Modelled as a ladies arm, the hand holding a bunch of grapes. Gilt bronze hinged cover. Length 8.5 cm. Provenance: Provenance: Sotheby's Dec Arts, Melbourne, 2001.

Meissen Porcelain Spaniel Perfume Bottle

A Meissen porcelain perfume bottle and stopper, in the form of a spaniel standing on its hind legs. German 19th century. Height 7.5 cm. Provenance: Sotheby's, Decorative Arts, Melbourne, 2001, the collection of Dr Trevor Hyde, Sydney, acquired from the…

Meissen Lady Perfume Bottle with Dog Stopper

A Meissen porcelain perfume bottle and stopper, modelled in the form of a lady holding a dog under her left arm, in a purple striped dress and yellow bodice. German 19th century. Height 8 cm. Provenance: Sotheby's, decorative Arts sale, Melbourne, 2001,…

Meissen Porcelain Man with Dog Perfume Bottle

A Meissen porcelain perfume bottle, in the form of a man holding a dog under his arm in red breeches and yellow cuffed and collared white coat. German 19th century. Height 8.5 cm. Provenance: Sotheby's, decorative Arts, Melbourne, 2001

Meissen Scent Bottle with Boy and Goat Scene

A rare Meissen scent bottle, moulded with scene of boy holding horns of goat, moulded stopper, gilt mounted, underglazed blue crossed swords, first half of 19th century, height 8 cm

Flirtatious Shepherd Porcelain Perfume Bottle

A Sitzendorf porcelain figural perfume bottle, 19th century, after Meissen depicting a flirtatious shepherd and a reluctant shepherdess beside a tree with a sheep and a tree top stopper in polychrome enamels, blue crossed marks underside, height 10 cm

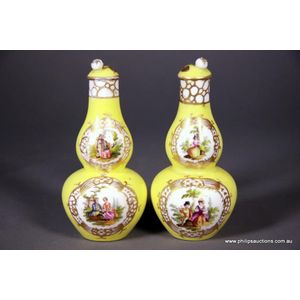

Meissen Porcelain Romantic Couple Perfume Bottles

A pair of Meissen porcelain perfume bottles, later 19th century, the double gourd bottles with small domed and floral embellished covers, each decorated with painted and gilded cartouches of romantic couples in the manner of Watteau; with double crossed…

Meissen Scent Bottle with Woman and Dog Stopper

A Meissen scent bottle, 19th century, the petite bottle modelled as a young woman in 18th century dress with a stripe and floral skirt, and mauve blue bodice, holding a large dog with a chain and collar, its head forming the stopper of the bottle; crossed…

Loading more...

Loading more...